|

|

Multi Cut Saw

Kiln dried

wood is carefully selected and cut to exact tolerances. The process

begins with this multi-cut saw, capable of making up to six different

angle cuts per board, to endure accuracy and consistency. |

|

|

Truss

Machine

Royal

Homes builds its own trusses to ensure that our high pitched roofs and

vaulted custom ceilings are as accurately constructed as the rest of

the home. Here the proper configuration, mechanically held in position

and truss plated together by a hydraulic press.

|

|

|

|

|

|

|

|

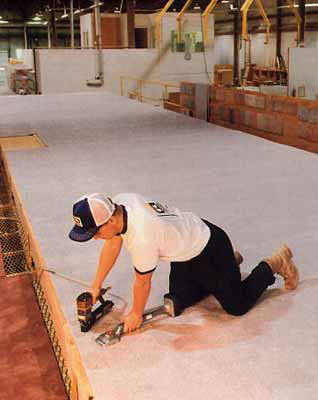

Floor

Framing

The framed

floor is placed in a jig and hydraulically squeezed to ensure it is

square. Tongue and groove 5/8" plywood is glued and power nailed in

place with coated nails. The heat generated by the driving force of

the nailer melts the coating to form a bond with the wood to increase

the holding strength and eliminate squeaky floors. |

|

|

|

|

|

|

Electrical

The floor

is raised to a convenient height to eliminate the problems of coping

with a ladder. Following a template on the floor, electricians drill

holes and string the electrical wires. This allows for a much neater

installation of Royal Homes' standard 200 amp. service. A service that

has the power to meet your needs, including future expansion. |

|

|

|

|

|

|

|

Floor Coverings

The floor coverings you choose are installed before

the walls are set in place, allowing for consistent stretching with no

bulges or poorly matched, oddly place seams. Underlay is glued in

place wherever vinyl is laid. Finally, two layers of plastic protect

the floor as it moves to the next work station. |

|

|

|

|

|

|

Ceiling

Rather than fight gravity, the ceiling are built

"upside down" so that gravity actually assists us. The installation of

a continuous vapour barrier eliminates the breaks at inside partition

walls commonly found in on-site construction. That means reduced heat

loss, then, for a superior finish, we cross strap the trusses, glue

and power screw the ceiling drywall in place to avoid future nail pops

or bulges.

|

|

|

|

|

|

|

|

Insulation

Walls are caulked and sealed at outside joints.

Because the walls have already been interior dry walled when put in

place, we can caulk and seal all electrical boxes, and then apply

insulation from the outside. An impossible task for the outdoor

builder, our insulating methods result in a superior, energy efficient

home. Exterior plywood sheathing, is glued and power fastened for

superior holding. |

|

|

|

|

|

|

Roofing

Because the roofing plywood is protected from the

elements and completely dry in our controlled building environment it

can be power nailed in position without rush or fear of damage. Then

your choice of coloured shingles, or other roofing material selected

from our wide range of samples, are installed. Many of our roofing

products come with a twenty year warranty or even longer.

|

|

|

|

|

|

|

|

Interior Finishing

Skilled drywallers, plasterers and painters work in

harmony to complete the interior of your home. Trim carpenters install

custom touches like French doors or crown moldings and complete the

kitchen area to exacting standards. From start to finish your Royal

Home is under the constant scrutiny of our quality assurance team and

subjected to over 247 control point inspections. |

|

|

|

|

|

|

Transport

Finally, ready for the big day, the modules of your

home are covered in a protective plastic membrane and placed on our

custom built "air-ride" flatbeds, specially designed from the safe

transportation of your new home. Drivers, employed by Royal Homes full

time, an advance crew and our site installation team accompany your

new home to its final destination.

|

|

|

|

|